The PRO-GSD is designed for use on commercial/industrial sliding doors or sliding fire doors. Commercial/Industrial continuous duty belt drive horizontal sliding door operator. When ordering a PRO-GSD operator, supply us with the following information:

- Door height

- Door width

- Door weight

- Horsepower

- Voltage/Phase

- Safety devices

- Mounting (LH or RH)

- If door opens to the left or right

- Options

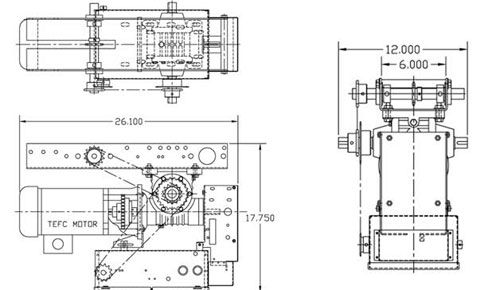

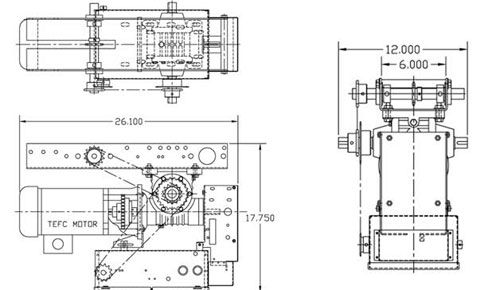

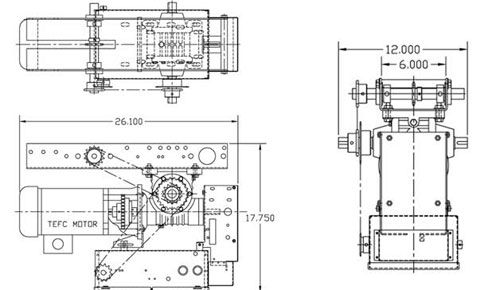

Dimensions

-

- 2 year Warranty

- 3 Control Circuit Options Avalaible: l- (M) Heavy duty reversing contactor with mechanical & electrical interlock incorporating the new UL325 (2010) Interface Module. *(2 factory wiring standard (constant pressure close), B2 wiring can be field set by moving 1jumper and installing Micanan monitored fail safe photo-eyes (supplied) or (optional) Micanan compatible monitored fail safe electric edge 2- (E) Full Function Smart 10.0 Logic control board featuring on-board receiver with antenna, enhanced program selections to include B2, C2, D1, E2, T & TS and supplied with Micanan monitored fail safe photo-cells or (optional) Micanan monitored fail safe electric edge *01 factory pre-set mode of operation standard (constant pressure open & close) 3- Heavy duty reversing contactor with mechanical & electrical interlock. (Not available in US or other areas where UL325 (2010) is mandated) *C2 factory wiring standard, B2 wiring can be field set by moving 1jumper. Provisions for standard reversing devices.

- 24V class 2 control circuit with 40VA transformer to protect against

- shortcircuit

- External radio control terminal strip

- Lowfriction powder metal limit cam nuts with fully adjustable rotary type

- limit switch assembly

- Three button open-close-stop control station Nema-l

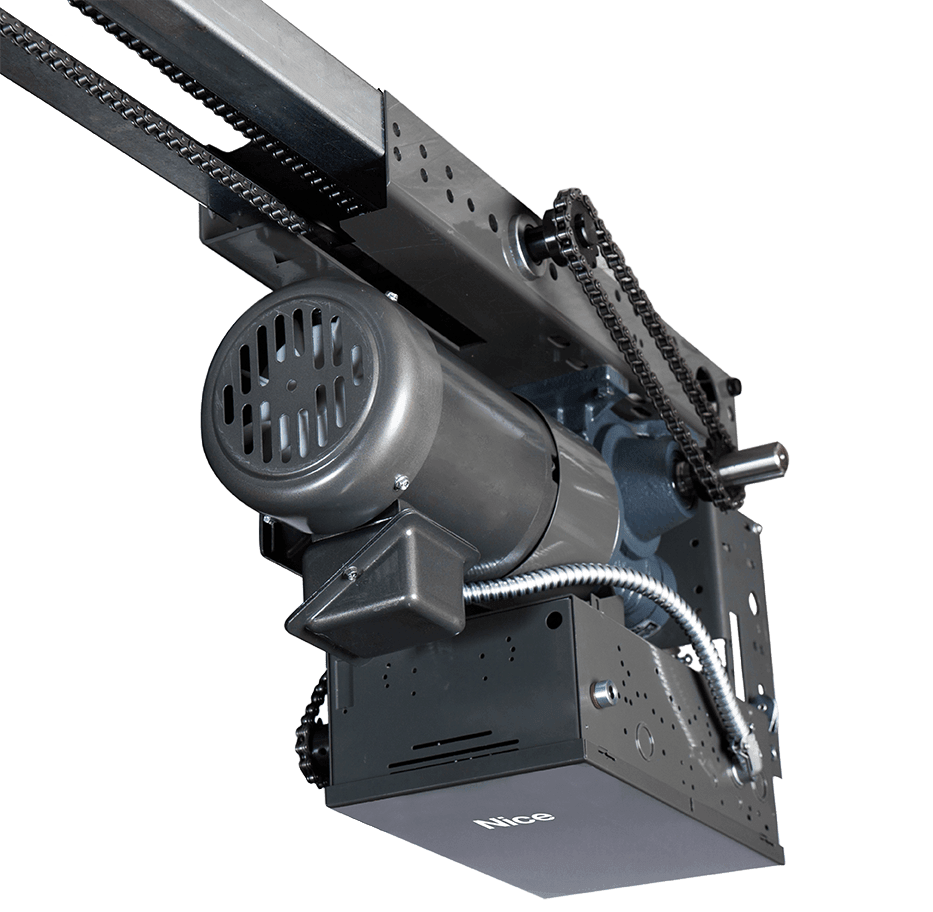

- Continuous duty industrial motor with external reset overload protection

- (l-phase) or external thermal overload relay protection (3-phase)

- Motor removable without affecting limit settings

- Heavy duty worm gear reduction in oil bath gearbox

- Adjustable in-line friction clutch

- Solenoid brake standard

- 1" permanently lubricated & sealed ball bearings on final drive shaft

- Emergency qUick release disconnect for manual operation

- #41 roller chain drive on trolley rail assembly

- Heavy duty sliding door hardware & hanging brackets included

- Trolley track for doors up to 12'standard

- Door speed 8" per second

- Bi-parting door modification available (optional)

- Baked on dark grey coat finish

- Shipping weight 140 Ibs (excludes rails)

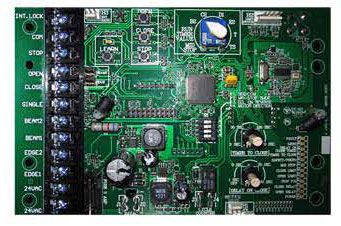

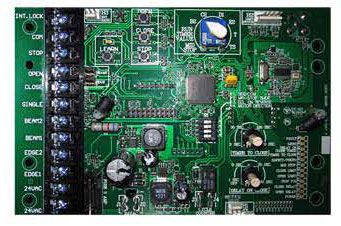

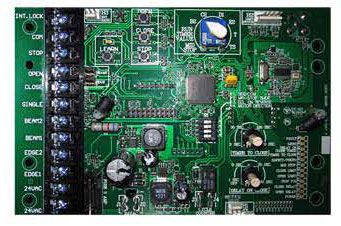

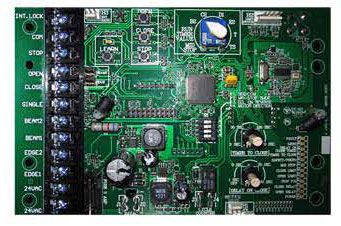

NEW SMART 10.0 LOGIC BOARD

- On-board open, close, stop pushbuttons

- Built-in 372 Mhz radio receiver

- Programmable timer to close

- Programmable mid stop' Maximum run timer

- 1.5 sec time delay reverse

- Programmable delay on close

- On-board fuse protection.

- Plug in board option.

- New vision lights

- 2 year Warranty

- 3 Control Circuit Options Avalaible: l- (M) Heavy duty reversing contactor with mechanical & electrical interlock incorporating the new UL325 (2010) Interface Module. *(2 factory wiring standard (constant pressure close), B2 wiring can be field set by moving 1jumper and installing Micanan monitored fail safe photo-eyes (supplied) or (optional) Micanan compatible monitored fail safe electric edge 2- (E) Full Function Smart 10.0 Logic control board featuring on-board receiver with antenna, enhanced program selections to include B2, C2, D1, E2, T & TS and supplied with Micanan monitored fail safe photo-cells or (optional) Micanan monitored fail safe electric edge *01 factory pre-set mode of operation standard (constant pressure open & close) 3- Heavy duty reversing contactor with mechanical & electrical interlock. (Not available in US or other areas where UL325 (2010) is mandated) *C2 factory wiring standard, B2 wiring can be field set by moving 1jumper. Provisions for standard reversing devices.

- 24V class 2 control circuit with 40VA transformer to protect against

- shortcircuit

- External radio control terminal strip

- Lowfriction powder metal limit cam nuts with fully adjustable rotary type

- limit switch assembly

- Three button open-close-stop control station Nema-l

- Continuous duty industrial motor with external reset overload protection

- (l-phase) or external thermal overload relay protection (3-phase)

- Motor removable without affecting limit settings

- Heavy duty worm gear reduction in oil bath gearbox

- Adjustable in-line friction clutch

- Solenoid brake standard

- 1" permanently lubricated & sealed ball bearings on final drive shaft

- Emergency qUick release disconnect for manual operation

- #41 roller chain drive on trolley rail assembly

- Heavy duty sliding door hardware & hanging brackets included

- Trolley track for doors up to 12'standard

- Door speed 8" per second

- Bi-parting door modification available (optional)

- Baked on dark grey coat finish

- Shipping weight 140 Ibs (excludes rails)

NEW SMART 10.0 LOGIC BOARD

- On-board open, close, stop pushbuttons

- Built-in 372 Mhz radio receiver

- Programmable timer to close

- Programmable mid stop' Maximum run timer

- 1.5 sec time delay reverse

- Programmable delay on close

- On-board fuse protection.

- Plug in board option.

- New vision lights

-