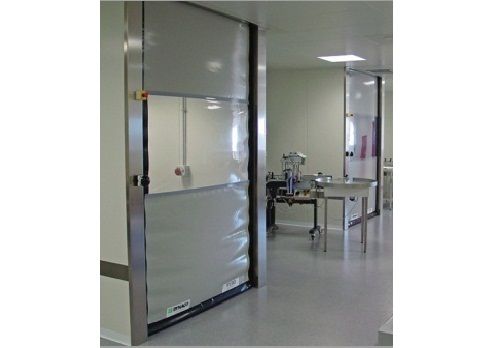

Dynaco M2 Cleanroom high speed door

The Dynaco M2 CLEANROOM is designed for an interior environment type cleanroom class 10,000 to 100,000 (according to Fed/Std 209 E) demanding a limitation of the leak flow at a difference in pressure up to 0.82 lbs/sq ft. (drafts of 19 MPH indicative, not including any multiplication coefficients taking into account the configuration of the building). The M2 CLEANROOM door is recommended for inside environments requiring cleanroom class contamination control.

Colours

White

White Blue

Blue Grey

Grey Yellow

Yellow Black

Black Orange

Orange Red

Red Green

GreenStandard Dimensions

18' W x 18' HOpening Speed

96 in/sClosing Speed

48 in/sOperating Type

Gear driven, push-pull movementSide Guide

Made of structural channels or 3 1/8" x 1 5/8" x 1/8" in steel + frame cover or 3 1/8" x 1 5/8" x 0.078" in stainless steel (optional).Inner Side Guide

Polyethylene (PE-UHMW 1000); outer section 7/8” x 1 9/16” fixed at the base of structural channels with closed nuts, without springs. The design provides a tight superior seal for demanding clean room applications.Side Guide Covers

Galvanized SteelDrum

In steel, diameter 4" x 0.078", shafts in steel. Shafts and flanges are welded interior and exterior of the drum.Door Curtain

Very resistant PVC (27 oz/sq.yd). Available in different colors and provided with side sealing zippers (Section 5/8” x 1/2”). The soft bottom edge design is completely enclosed and hermetically sealed for ease of cleaning.Motor

Without brake, with 4 poles, controlled by a variable speed drive. Power: 2 HP. Protection degree NEMA 4.Gearbox

Size 50 for a motor of 1 HP and gear reduction ratio 1/7; size 63 for 2 HP.Detectors

An infrared photocell, installed inside the frame and detecting the presence of a pedestrian or a vehicle, immediately opens the door and keeps it open as long as the presence is detected. Height of the photocell: 12” from the floor. (Optional: up to maximum 24” upon request). A bottom edge detector opens the door when it hits an obstacle during the closing cycle. This detector is positioned at the bottom part of the curtain.Power Supply

Standard: single phase 208-230 VAC, three phase 208-230 VAC, three phase 460 VAC. Optional: three phase 575 VAC. Frequency: 50-60 Hz. Fuses to be provided by the customer: 10 A for a motor of 1 HP and 16 A for 2 HP.Space Requirements

All indicated dimensions are net: the space necessary for mounting and maintenance has to be provided. Reduced dimensions: upon request.- Designed for cleanroom class operations requiring limitation in leak flow of up to 0.82 lbs per square foot per federal standard 209E.

- Maximum standard dimensions 18' x 18'.

- Curtain made of PVC reinforced vinyl.

- Operating speed up to 96"/sec.

- Infrared photocell in side guides.

- Soft bottom edge.

- Pneumatic bottom edge detector.

- Designed for interior contamination control in the pharmaceutical, electronic, hospital, laboratory or other controlled environments.

- Pharmaceutical

- Electronic

- Hospitals

- Laboratories

- Controlled Environments

Colours

Colours

White

White Blue

Blue Grey

Grey Yellow

Yellow Black

Black Orange

Orange Red

Red Green

GreenFeatures

Standard Dimensions

18' W x 18' HOpening Speed

96 in/sClosing Speed

48 in/sOperating Type

Gear driven, push-pull movementSide Guide

Made of structural channels or 3 1/8" x 1 5/8" x 1/8" in steel + frame cover or 3 1/8" x 1 5/8" x 0.078" in stainless steel (optional).Inner Side Guide

Polyethylene (PE-UHMW 1000); outer section 7/8” x 1 9/16” fixed at the base of structural channels with closed nuts, without springs. The design provides a tight superior seal for demanding clean room applications.Side Guide Covers

Galvanized SteelDrum

In steel, diameter 4" x 0.078", shafts in steel. Shafts and flanges are welded interior and exterior of the drum.Door Curtain

Very resistant PVC (27 oz/sq.yd). Available in different colors and provided with side sealing zippers (Section 5/8” x 1/2”). The soft bottom edge design is completely enclosed and hermetically sealed for ease of cleaning.Motor

Without brake, with 4 poles, controlled by a variable speed drive. Power: 2 HP. Protection degree NEMA 4.Specifications

Gearbox

Size 50 for a motor of 1 HP and gear reduction ratio 1/7; size 63 for 2 HP.Detectors

An infrared photocell, installed inside the frame and detecting the presence of a pedestrian or a vehicle, immediately opens the door and keeps it open as long as the presence is detected. Height of the photocell: 12” from the floor. (Optional: up to maximum 24” upon request). A bottom edge detector opens the door when it hits an obstacle during the closing cycle. This detector is positioned at the bottom part of the curtain.Power Supply

Standard: single phase 208-230 VAC, three phase 208-230 VAC, three phase 460 VAC. Optional: three phase 575 VAC. Frequency: 50-60 Hz. Fuses to be provided by the customer: 10 A for a motor of 1 HP and 16 A for 2 HP.Space Requirements

All indicated dimensions are net: the space necessary for mounting and maintenance has to be provided. Reduced dimensions: upon request.Other Details

- Designed for cleanroom class operations requiring limitation in leak flow of up to 0.82 lbs per square foot per federal standard 209E.

- Maximum standard dimensions 18' x 18'.

- Curtain made of PVC reinforced vinyl.

- Operating speed up to 96"/sec.

- Infrared photocell in side guides.

- Soft bottom edge.

- Pneumatic bottom edge detector.

- Designed for interior contamination control in the pharmaceutical, electronic, hospital, laboratory or other controlled environments.

Applications

- Pharmaceutical

- Electronic

- Hospitals

- Laboratories

- Controlled Environments